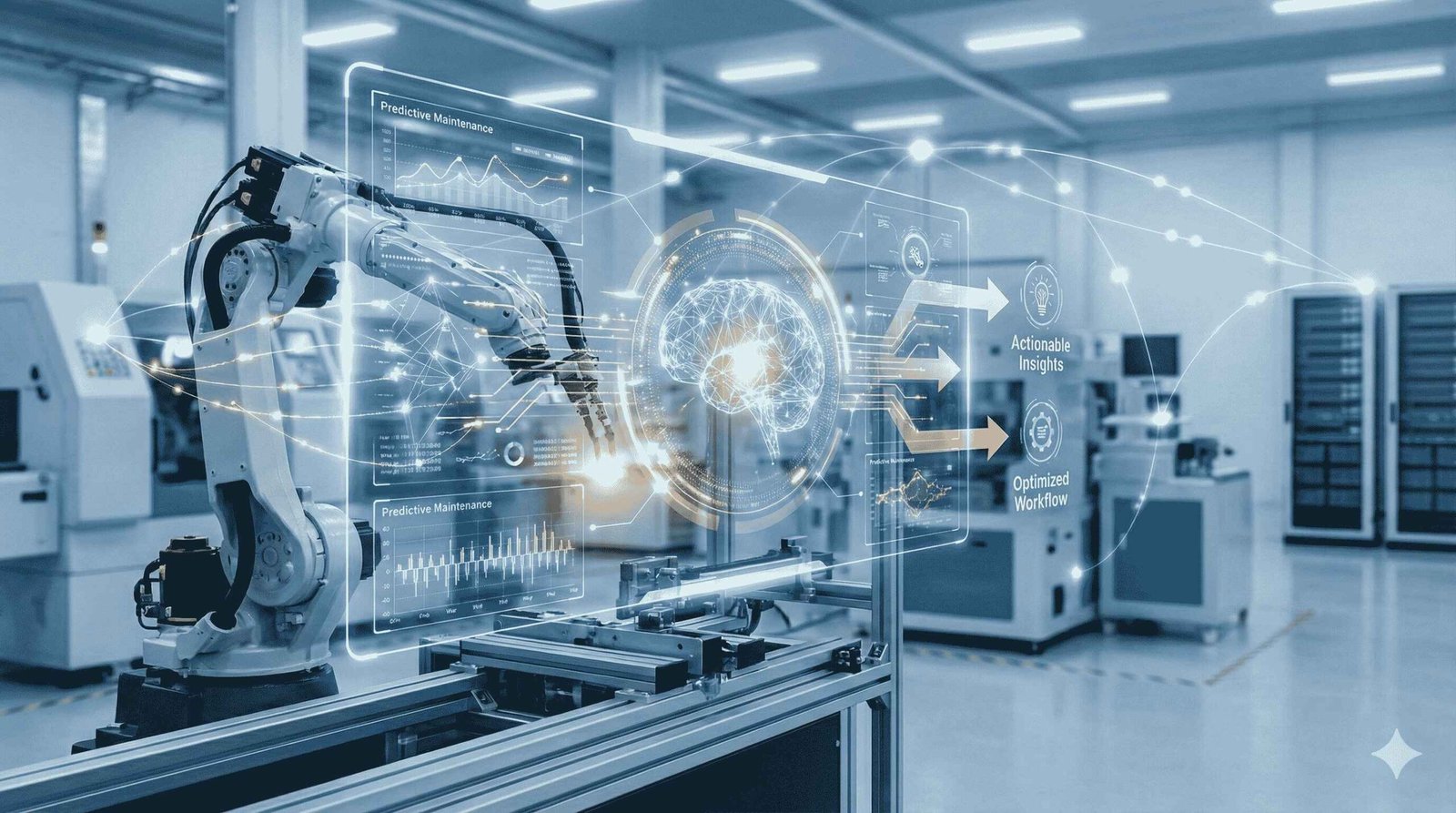

The Industrial IoT (IIoT) systems play a vital role in delivering data across various machines, systems, and other industrial devices. Data is gathered via sensor readings, machine logs, performance signals, etc. As data is in a constant state of flux, companies can benefit from it by using valuable insights derived from it. However, the way we interpret data decides the productivity of companies. IIoT platforms make use of this data and turn them into actionable insights that eventually help in predicting outcomes and fastening operations in companies. Moreover, these platforms act as a connecting bridge between factory floors and IT systems.

But how do we make the best use of data gathered from these devices? This is where AI and Machine Learning (ML) help reshape the industrial landscape. IIoT platforms with the help of analytics gained from AI and ML fosters decision-making. They can highlight risks by keeping a watch on real-time operational data. With this data, companies can undertake strategies that boost efficiency.

As manufacturing industries need to function efficiently, due to various business reasons, there’s pressure amongst them to reduce downtime and optimize performance so that they stay competitive in the market. Artificial intelligence and Machine learning in IIoT platforms when coupled together, it helps businesses in deriving key data insights, equipping humans to work smarter and faster. They are proficient in providing analytics not on what happened but how to avoid anomalies or what to do next. In short, they help us get ready for the future.

They support IIoT platforms in the following ways:

- Identify anomalies and other discrepancies hidden within massive datasets.

- Help forecast failures before they occur.

- Optimize processes without requiring human assistance.

- Provides improvised decisions backed by data insights.

The result? Delivering a smarter, faster, industrial environment using data-driven insights.

Features Strengthening IIoT Platforms Using AI and ML

1. Predictive Maintenance

As we know, in manufacturing units, there exist high level machines, and a mal- functioning of a single unit hampers the entire production flow when things come to a standstill. When a machine breaks down, repairs and maintenance can be expensive. With the emergence of IIoT platforms, we can predict the health of machines and equipment failures much before its occurrence. These platforms can analyze data at various levels about fluctuations in temperature, pressure, vibrating sound etc. In this way, companies can initiate actions for resolving anomalies and bottlenecks, thereby saving time with costly repairs and unexpected downtime.

Benefits:

- Reduced downtime

- Lower maintenance costs

- Longer equipment lifespan

- Scheduling maintenance of repairs

2. Real-Time Anomaly Detection

Anomaly detection is one of the core functionalities of IIoT platforms. As IoT sensors are constantly generating enormous data, it helps in detecting anomalies using data points that deviate from the usual pattern of functioning.

In the case of industrial environments, a minor defect in a machine can escalate into major production issues. All these AI algorithms continuously monitor and scan equipment data using sensors. This helps in identifying abnormalities in equipment functioning be it in the form of a temperature variation or unusual motor behavior; this can enable companies to take proactive decisions.

Benefits:

- Prediction of risks with immediate alerts signaling abnormalities

- Faster troubleshooting

- Better quality control

- Reducing downtime and maintenance costs

- Reducing wastage

- Intelligent Process Optimization

AI and ML capabilities in industrial IoT platforms can equip factories with greater operational efficiency. Moreover, they can carefully monitor production cycles, resource usage, and machine performance. This helps in providing useful information on identifying the cause of inefficiencies that affect their proper functioning. Previously, traditional manufacturing processes relied heavily on manual inputs that eventually turned out to be more time-consuming. Now humans need to interfere less with the operational workflow. To achieve optimal results, there should be a collaborative set up where humans and AI-driven processes work together.

With the implementation of AI/ML, they can recommend:

- Optimal time for planning production schedules

- Energy-saving opportunities

- Ideal machine configurations

- Automated process adjustments

With the passage of time, the system learns from historical data, and it analyzes contexts. This significantly improves operational efficiency without manual intervention.

- Quality Assurance with Computer Vision

AI-driven vision systems inspect products in real time, detecting defects impossible to catch manually. They can even spot minor defects like dents and surface scratches which could be overlooked by the human eye. This enables swift corrective measures without waiting for manual checks. Along with IIoT data, they create a closed-loop feedback mechanism for automated corrections.

Applications include:

- Assembly line inspection: Ensuring that each part in the production line is assembled correctly.

- Packaging quality checks: Checks whether seals and labels are properly formatted, avoiding any sort of damage.

- Surface and texture analysis: Analyzing whether dents and uneven surfaces on products are analyzed.

- Material defect detection: Thoroughly verifies impurities and deformities once they are pushed in for production.

This eventually helps with driving consistency, speed, and accuracy across quality control processes.

- Supply Chain Visibility and Optimization

IIoT can be utilized in the best way to track assets, inventory, and shipments. Using IoT, several operations are automated such as warehouse operations, optimizing resources, and space utilization. With ML, this data becomes actionable, and it helps in:

- Predicting delays

- Recommend alternate routes

- Optimize stocking levels

- Forecast demand more accurately

- Track packages and estimated delivery time.

AI/ML ensures supply chains stay resilient with improved oversight and reduced costs.

Key Technologies Powering AI in IIoT

- Digital Twins: Using this technology, industries can simulate the functioning of equipment in their respective factories at a convenient location, thereby monitoring data in real-time. This saves them time to travel to their respective geographical location for monitoring. It paves the way for smarter forecasting and proactive problem–solving.

- Edge Computing: Allows data to be analyzed close to where it is needed as opposed to traditional systems where it used to be sent to a cloud for processing. Since AI is directly placed on the sensors, machines or other near-by devices, it can monitor information without any delays.

- Time-series forecasting models: A time-series data AI model help with forecasting data on key factors related to temperature, pressure, energy consumption. This helps with forecasting the outcome. By analyzing past trends, patterns, and changes, it can forecast future values.

- Reinforcement learning: This technology nables continuous process improvement and improvising decision-making capabilities. They do not continuously rely on historical data but learn from context and improvise the output each time.

- Natural Language Interface (NLI): Makes exchange of information much easier in the same manner as we talk to humans. Therefore, it is easily accessible to even non-technical users to get insights and generate reports with an absolutely no-coding background.

Challenges to Consider

There are several challenges with AI and ML powered analytics in IIoT platforms, although it has immense benefits in manufacturing workflows by way of enhancing production efficiency. Although they have the potential to revolutionize the way we live, we need to be prepared for its challenges too. The first and foremost challenge is to manage the humungous data generated from these IoT devices. Moreover, these AI/ML needs to be trained with data in order to produce the best output. Another concern is dealing with data security issues. IoT devices that are deployed in insecure environments are prone to cyber- attacks. One should safeguard the data generated from these devices against attacks. The third concern is about integration complexity. It may not be always feasible to connect sensors, machines, and software inside a factory set up. These could be legacy systems that were not built for connectivity. Different machines would be using varied communication protocols and hence setting up this connection requires technical expertise. This erupts as a challenge as it takes time and effort to merge the data from various sources.

Business Impact: Why It Matters

Implementing AI and ML-powered analytics in IIoT platforms paves the way for analyzing large data sets for improved decision-making. The data gathered using AI/ML analytics helps prevent bottlenecks in production and devise certain strategies that optimize cost. By carefully assessing data, production schedules can be planned in a sustainable way. Moreover, they enhance quality through various technologies such as predictive analytics, asset monitoring, edge computing, etc. The use of AI/ML fosters decision-making with automated insights. In short, such technologies make the industries future ready.

Conclusion

The role of AI and ML in IIoT platforms paves the way for intelligent command centers that help in not just understanding situations or contexts, but predictions and acts based on real-time data. We see a shift from manual data processes to AI-driven insights. This helps companies reduce their downtime, optimize processes, enhance quality, and enable smarter operational decisions. For businesses aiming at adopting these technologies, software development services that are AI-powered help transform your software into intelligent systems that evolve with ecosystems. The world of today is data-driven, and embedding these insights into the operational workflow can transform operations, giving a significant competitive edge to these companies.